MiCo

Heater

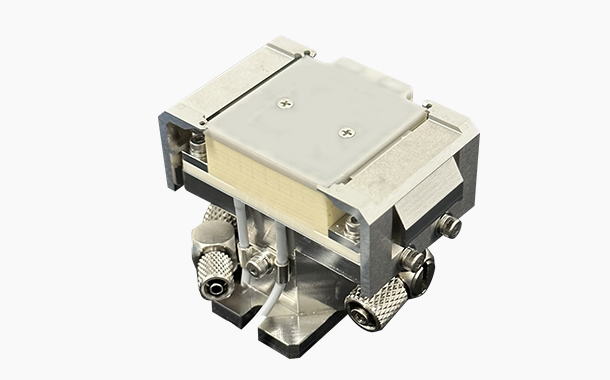

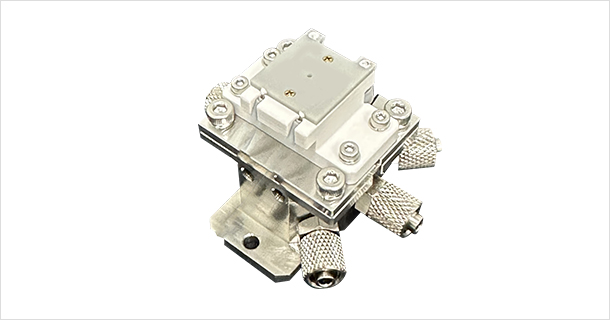

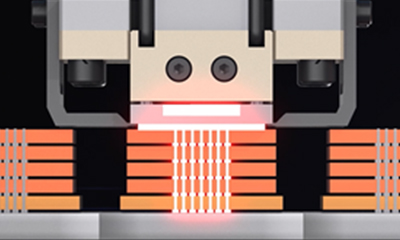

MiCo Heater is a functional component developed based on 20 years of accumulated ceramic material composition and sintering technology, as well as precision machining and bonding techniques.

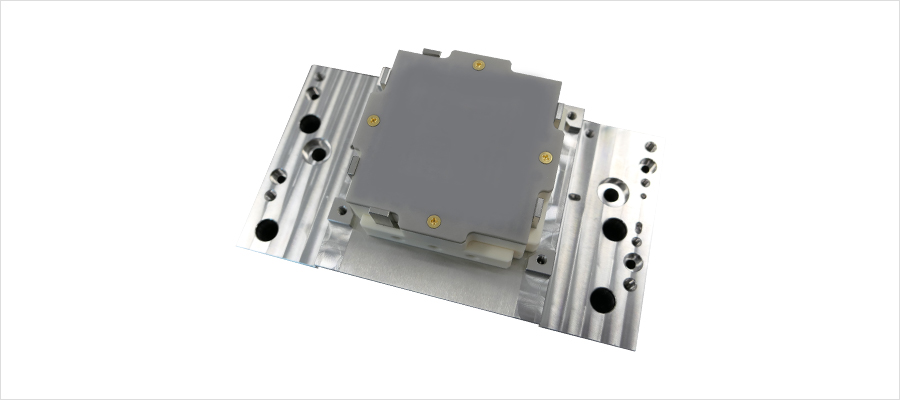

It enables high productivity by cycling through rapid heating and cooling and delivers uniform heat across the working surface based on excellent flatness and parallelism, resulting in the production of high-quality products. This key component is applied in the Advanced Packaging process, and MiCo manufactures and supplies Heaters in various forms using the materials it has developed.

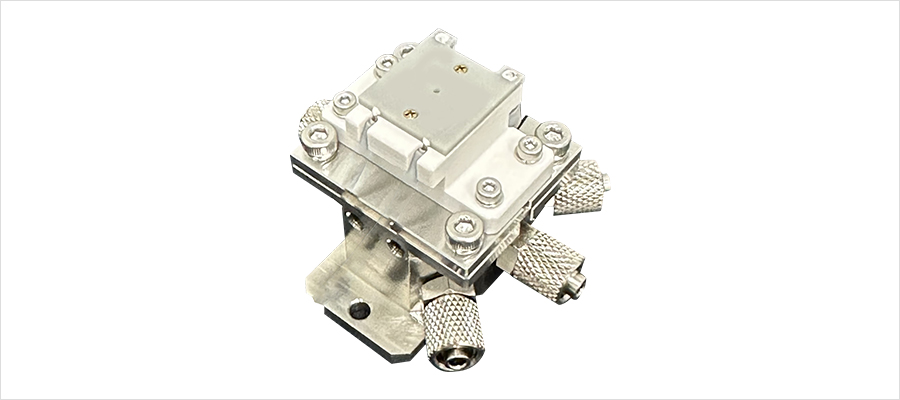

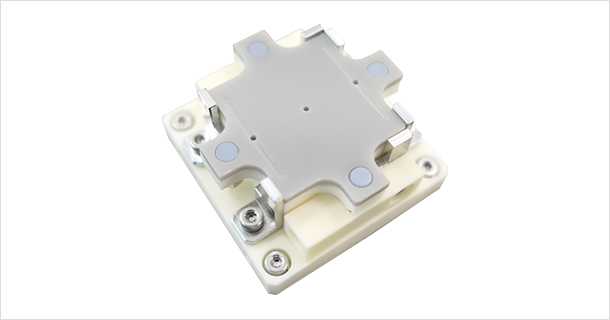

MPH 016

- · Working Zone : 16 x 16mm

- · Temp. Range : 50℃ → 450℃

- · Heating Speed : ≤ 1.5 sec.

- · Cooling Speed : ≤ 3 sec.

- · Load Capacity : ≤ 900N

- · Power Consumption : ≤ 1,538W

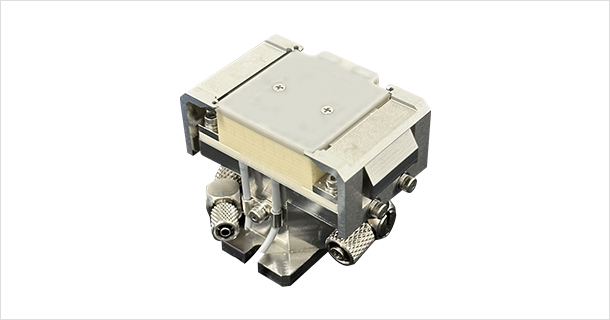

MPH 022

- · Working Zone : 22 x 22mm

- · Temp. Range : 50℃ → 450℃

- · Heating Speed : ≤ 1.5 sec.

- · Cooling Speed : ≤ 3 sec.

- · Load Capacity : ≤ 1,100N

- · Power Consumption : ≤ 1,982W

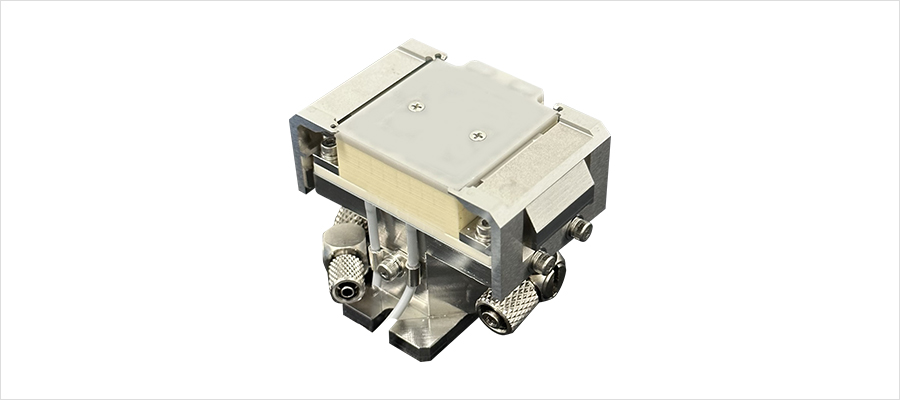

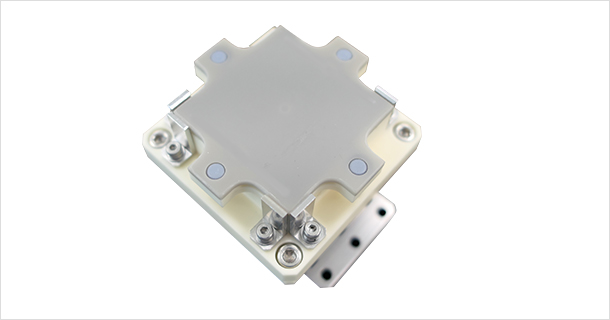

MPH 028

- · Working Zone : 28 x 28mm

- · Temp. Range : 50℃ → 450℃

- · Heating Speed : ≤ 2 sec.

- · Cooling Speed : ≤ 12 sec.

- · Load Capacity : ≤ 1,500N

- · Power Consumption : ≤ 2,688W

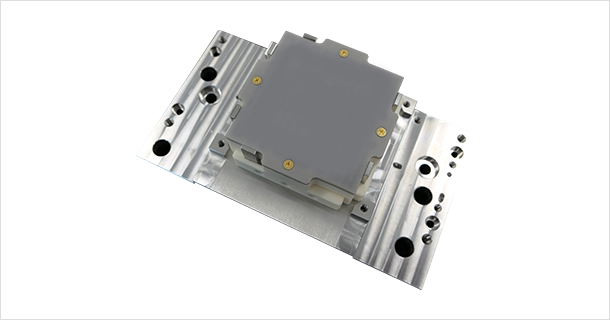

MPH 035

- · Working Zone : 35 x 35mm

- · Temp. Range : 150℃ → 450℃

- · Heating Speed : ≤ 3 sec.

- · Cooling Speed : ≤ 10 sec.

- · Load Capacity : ≤ 3,000N

- · Power Consumption : ≤ 6,050W

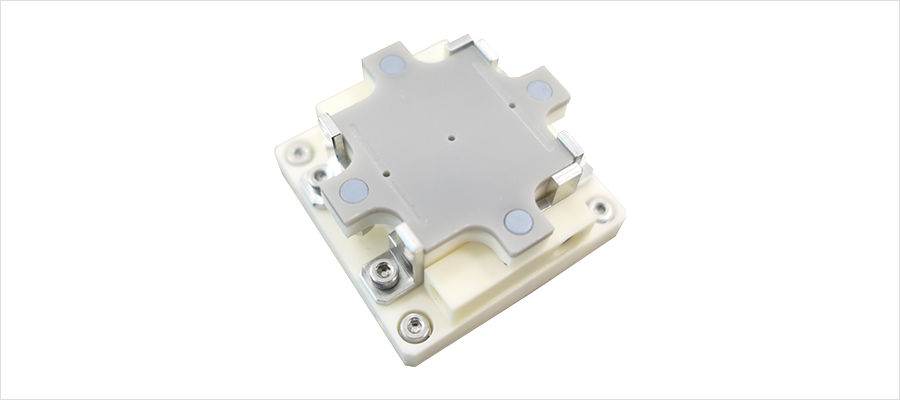

MPH 054

- · Working Zone : 54 x 54mm

- · Temp. Range : 50℃ → 450℃

- · Heating Speed : ≤ 22 sec.

- · Cooling Speed : ≤ 30 sec.

- · Load Capacity : ≤ 5,000N

- · Power Consumption : ≤ 5,700W

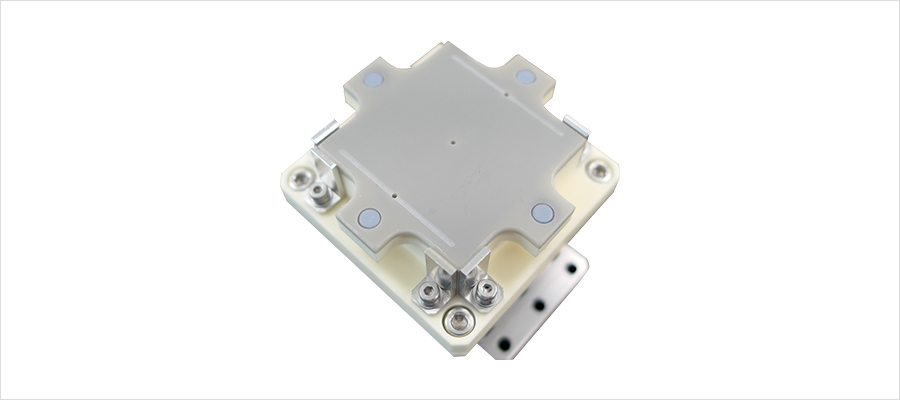

MPH 060

- · Working Zone : 60 x 60mm

- · Temp. Range : 50℃ → 450℃

- · Heating Speed : ≤ 22 sec.

- · Cooling Speed : ≤ 30 sec.

- · Load Capacity : ≤ 7,500N

- · Power Consumption : ≤ 5,000W

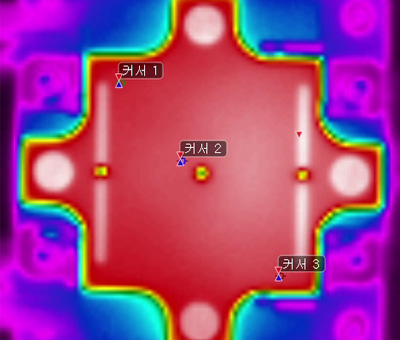

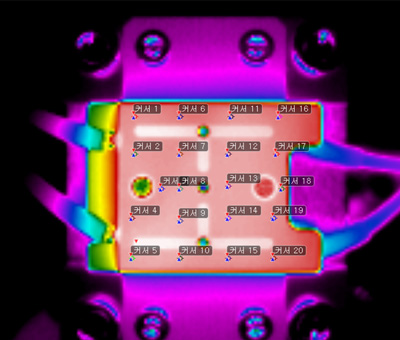

균일한 Heater 표면 열분포 구현

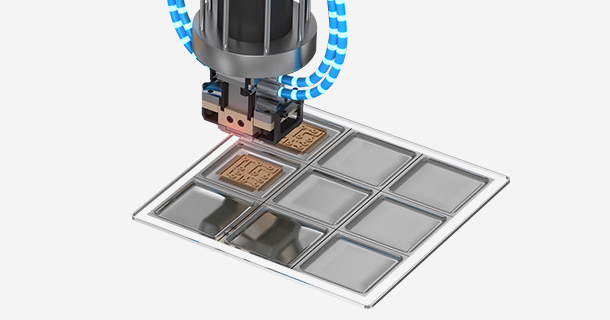

Application

Material for semiconductor post-processing equipment components

Packaging Process

Flip Chip Bonding

TC - Microbump Bonding

TC-NCF Bonding

HBM

AI Semiconductor