We provide customers with a variety of ceramic materials such as Al2O3 (Alumina), Y2O3 (Yittria), and AlN (Aluminium nitride).

These ceramic materials are used in manufacturing and coating parts for Semi-Conductor equipment, parts for display equipment and cells for solid oxide fuel cell (SOFC) systems.

-

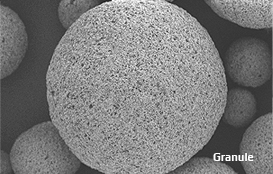

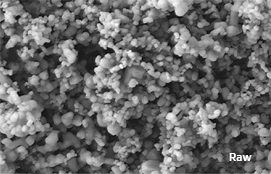

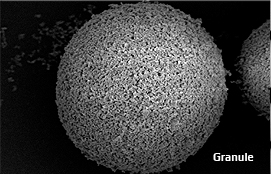

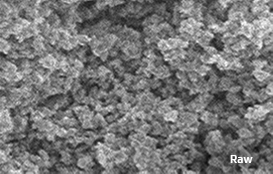

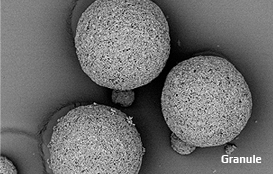

AIN Powder

Excellent Thermal Conductivity

Great Insulation Characteristics

High Corrosion Resistance

-

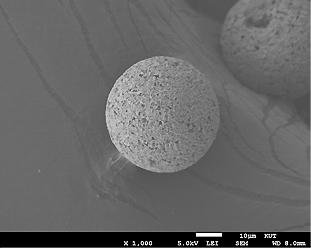

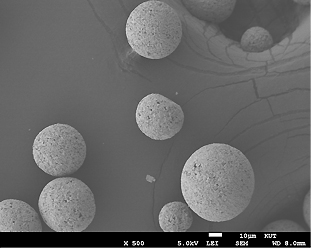

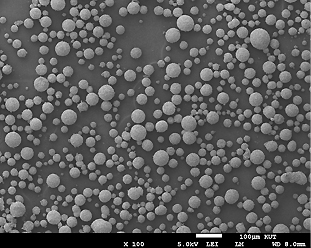

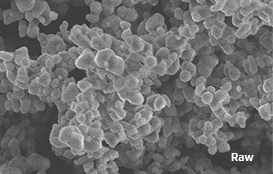

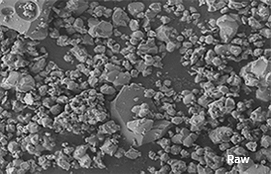

Al2O3 Powder

Excellent Hardness

High Wear Resistance

High Resistivity

-

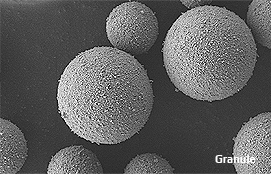

Y2O3 Powder

Excellent Heat Resistance

High Dielectric Properties

Chemical Stability

-

YAG Powder

Excellent Plasma Erosion Resistance

High Translucency

Excellent Machinability